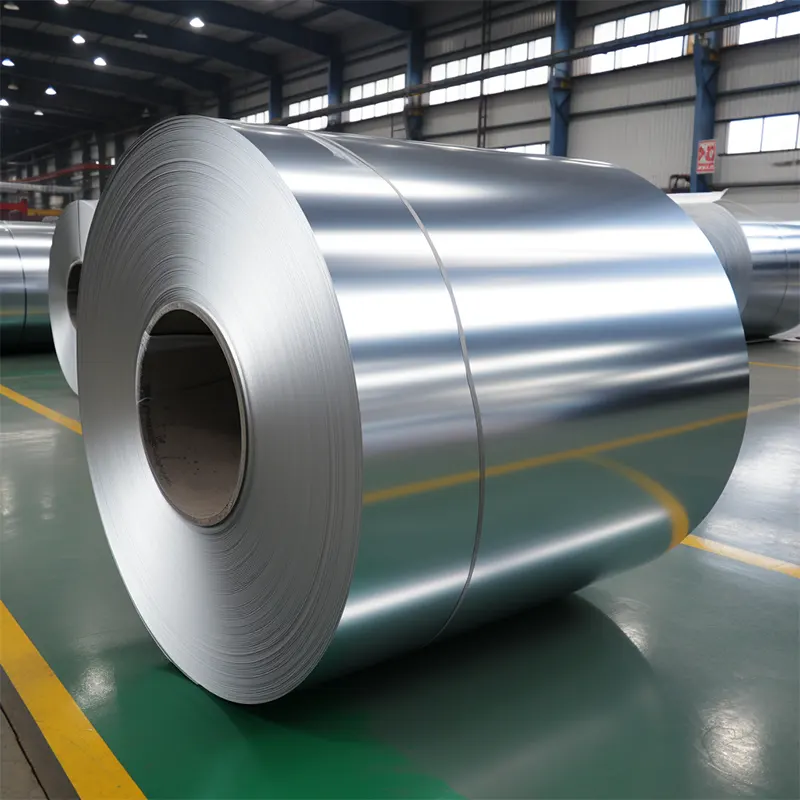

Material: Galvanized steel refers to steel plates that are coated with a layer of zinc to enhance their corrosion resistance. Common steel substrates include Q235 and Q345.

Application Fields: Galvanized steel is widely used in construction, automotive, household appliances, and machinery sectors. It is used to manufacture roof panels, wall panels, car bodies, appliance casings, and more, primarily to improve the corrosion resistance and lifespan of the steel.

Galvanized steel is a material with a zinc-coated surface, which can be treated through hot-dip galvanizing or electrogalvanizing. Hot-dip galvanizing involves immersing the steel plate in molten zinc, while electrogalvanizing deposits a zinc layer on the steel surface through an electrochemical reaction. Galvanized steel offers excellent corrosion resistance, strength, and toughness, making it suitable for use in various environmental conditions.

Material Types:

Steel Substrate: Typically hot-rolled or cold-rolled steel plates

Galvanizing Treatment: Hot-dip galvanizing or electrogalvanizing

Steel Standards:

Chinese Standards: GB/T 700 (Carbon Steel), GB/T 1591 (Low-Alloy High-Strength Structural Steel)

Steel Grades:

Q235: Carbon steel with a yield strength of 235 MPa

Q345: Low-alloy high-strength structural steel with a yield strength of 345 MPa

Galvanizing Layer Thickness:

Hot-Dip Galvanizing: Typically ranges from 40 μm to 200 μm

Electrogalvanizing: Typically ranges from 8 μm to 30 μm

Thickness:

Steel Plate Thickness: Typically ranges from 0.3 mm to 3 mm

Dimensions:

Width: Typically ranges from 600 mm to 1500 mm

Length: Common range from 1000 mm to 6000 mm, customizable based on requirements

Tensile Strength:

Q235: 370-500 MPa

Q345: 470-600 MPa

Yield Strength:

Q235: 235 MPa

Q345: 345 MPa

Corrosion Resistance:

Hot-Dip Galvanizing: Provides excellent corrosion resistance, suitable for harsh environments

Electrogalvanizing: Provides moderate corrosion resistance, suitable for ordinary environments

Surface Treatment:

Hot-Dip Galvanizing: Thick zinc layer with a rough surface, suitable for exposed environments

Electrogalvanizing: Thin zinc layer with a smooth surface, suitable for applications requiring high aesthetic quality

Do you have questions about best practices in steel bridge design for fabrication?

Need assistance with budget pricing, erecting, or shipping your structural steel?

Reach out to High Steel’s experts – we look forward to helping you.

Shandong Zhousheng Heavy Industry Technology Co., Ltd,was founded in 2016, the company is located in No.S5019, Guangming Avenue, Shizhong District, Zaozhuang City, Shandong Province.